4 Surprising Truths About the Humble Brick and Its Massive Impact on Our Climate

Introduction: The Hidden Story in Every Bricks Wall

The fired clay brick is one of humanity’s oldest and most universal building materials. For over 6,000 years, this simple block of baked earth has formed the walls of our homes, schools, and cities, feeling timeless and unassuming. Yet, behind this humble facade lies a story that challenges core assumptions about progress and proves that simple changes can have profound impacts.

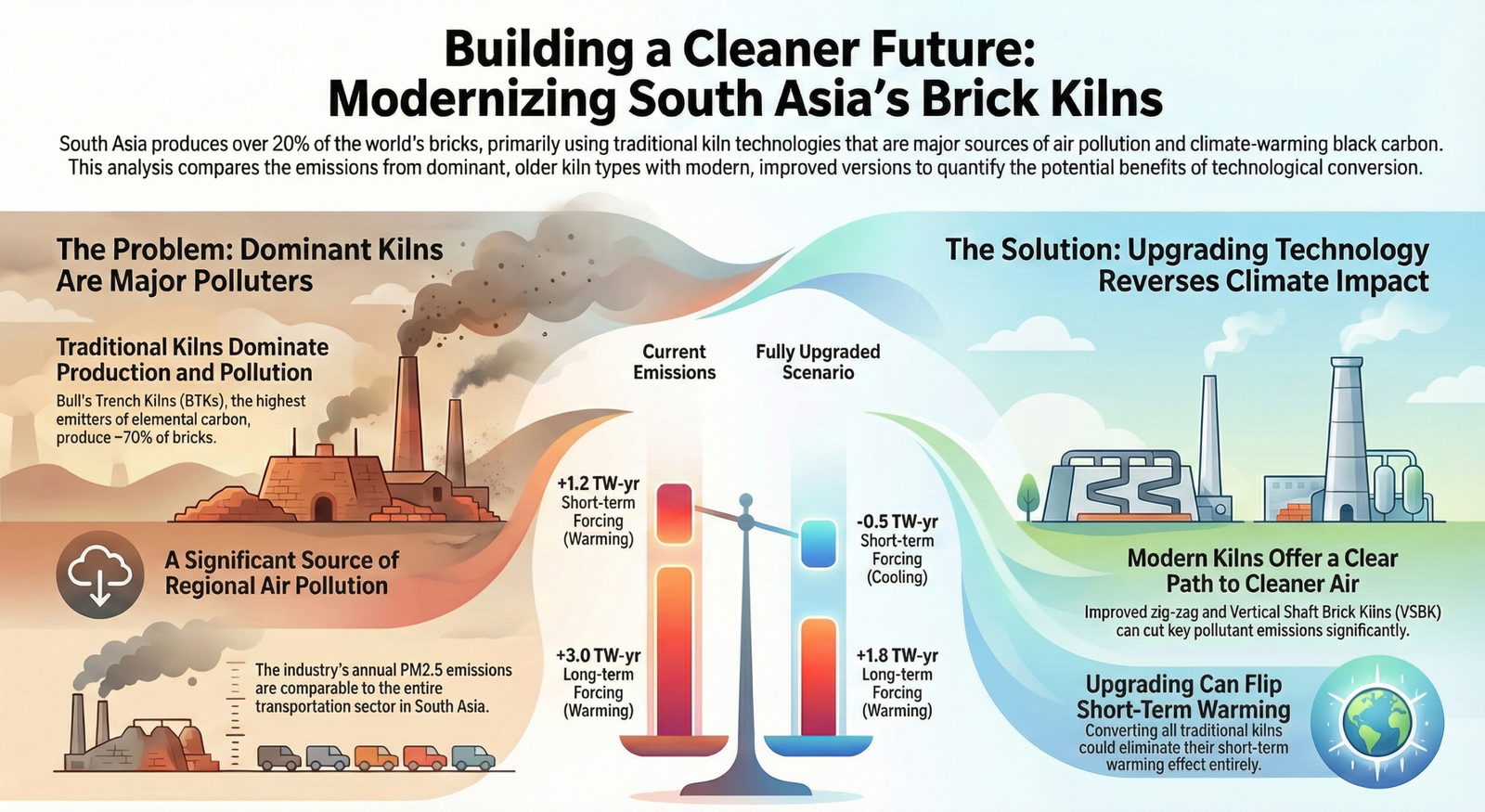

This story is urgent in South Asia, which produces over 20% of the world’s 1.5 trillion bricks annually. Most of these bricks are fired in traditional kilns that release vast quantities of air pollutants and climate-warming emissions. A recent scientific study involving direct measurements from kiln smokestacks has uncovered counter-intuitive truths about this ancient industry, revealing both hidden dangers and unexpected solutions.

Here are four surprising findings about the industry’s climate impact.

1. The “High-Tech” Solution Isn’t Always the Cleanest

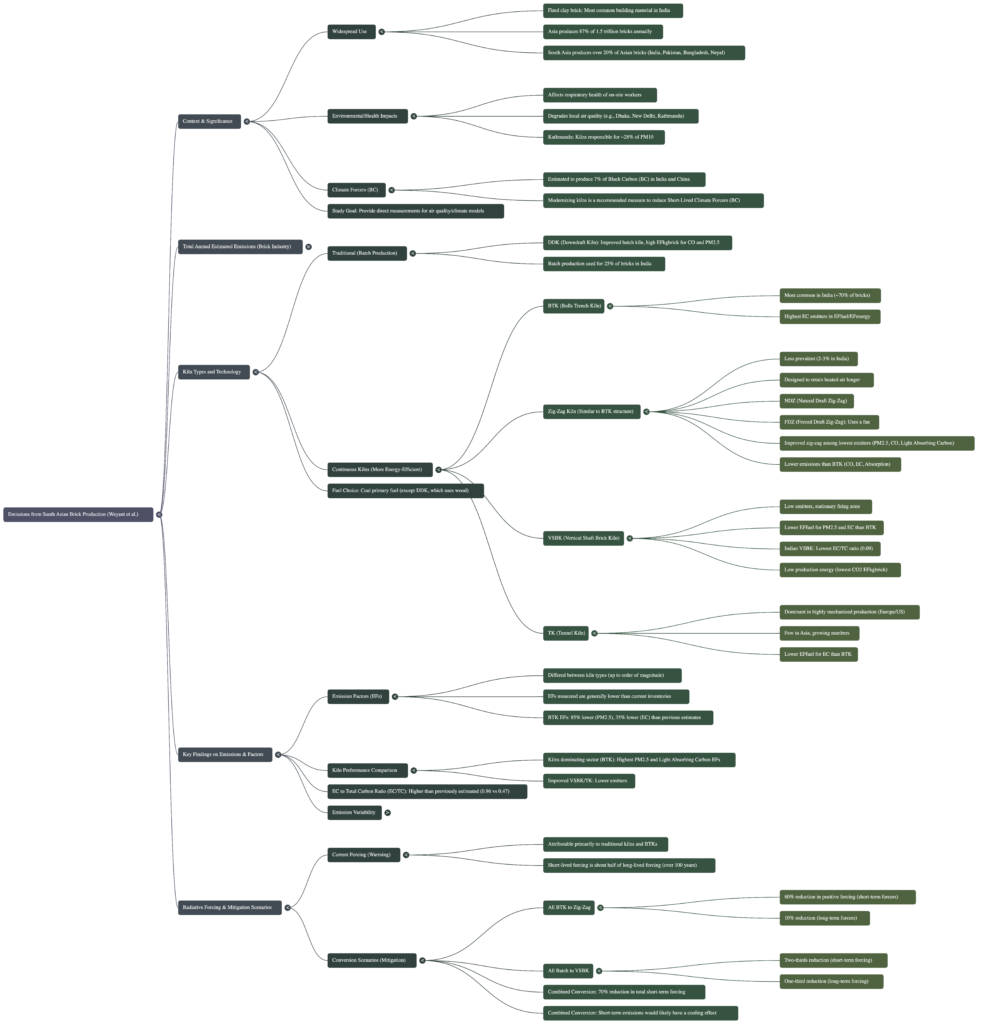

It is natural to assume that replacing old technology with modern versions is always a win for the environment—the myth of the silver bullet. In brick-making, advanced designs like the Vertical Shaft Brick Kiln (VSBK) and the Tunnel Kiln (TK) were expected to be beacons of clean production.

However, the study revealed a shocking twist: these supposedly improved kilns sometimes produced more carbon monoxide (CO), a toxic pollutant, than less advanced counterparts. The reason lies in their fuel; these kilns often use “internal fuels,” where coal is mixed directly into the clay, starving the fuel of oxygen during firing and causing incomplete combustion that generates high levels of CO. While more energy-efficient and producing less long-term CO2, their operational reality creates a serious air quality trade-off. This reveals that technology is only half the story; the way it is operated and fueled can undermine its intended benefits.

2. A Simple “Zig-Zag” Tweak Slashes Harmful Emissions

The Bull’s Trench Kiln (BTK) is the most common kiln in South Asia, producing an estimated 70% of all bricks in India. The study found it is also the single highest emitter of Elemental Carbon (EC), a key component of fine black soot that warms the atmosphere and harms health.

However, researchers identified a simple yet powerful modification: the zig-zag kiln. By stacking bricks in a zig-zag pattern, this design creates a heat maze that forces hot air to stay in the kiln longer, allowing for a cleaner burn of fuel and soot. The study found that zig-zag kilns had significantly lower emissions of both carbon monoxide and climate-warming Elemental Carbon compared to BTKs. Because the structures are similar, existing BTKs can be converted to this cleaner design, representing a major opportunity to slash pollution across the region.

3. Brick Pollution Has a Climate Footprint Rivaling Cars

To grasp the scale of the problem, the study’s analysis suggests that just one year of emissions from South Asian brick production has a long-term climate warming effect (integrated over 100 years) comparable to that of all passenger cars in the United States.

This impact comes from two types of emissions: “short-term” forcing from aerosols like black carbon, and “long-term” forcing from greenhouse gases like CO2. The analysis showed that converting the dirtiest kilns—BTKs and traditional batch kilns—to cleaner zig-zag and VSBK models would slash immediate, short-term warming forcing by a staggering 70%. In fact, this conversion could cause the net short-term climate effect of the industry’s emissions to switch from warming to cooling, as the dramatic reduction in warming black carbon allows the cooling effect of other emitted particles, like sulfates, to dominate.

4. We’ve Been Getting the Numbers Wrong

This groundbreaking study is critical because it relied on direct, on-the-ground measurements rather than older estimates, painting a more nuanced picture than before.

For the standard BTK, the new measurements brought surprising news: its emissions of climate-warming Elemental Carbon (EC) and health-damaging fine particulate matter (PM2.5) were actually 35% and 85% lower, respectively, than figures used in previous emission inventories. Yet, despite individual BTKs being cleaner than assumed, the new data suggests the total estimated Elemental Carbon emissions from the entire South Asian brick industry are greater than previous estimates used by major international bodies. This highlights that effective policy depends not just on measuring a single source, but accurately accounting for the entire scale of the industry through rigorous field science.

Conclusion: A Better Future, Built Brick by Brick

The environmental impact of making the simple clay brick poses a significant threat to regional air quality and the global climate. But this research delivers a clear message of hope: practical, high-impact solutions are available and surprisingly simple. Clever improvements to existing technology, like converting to a zig-zag design, can be far more effective than just adopting complex “high-tech” solutions that have their own trade-offs.